At RHEIN LIGHT, our primary goal is to provide high-quality lighting products and ensure that customers are satisfied and trust our products. We implement strict quality control protocols to detect and resolve any potential issues, ensuring that every lighting product meets the highest standards of reliability, functionality and safety before leaving the factory.

Quality Control Process

1. Incoming inspection: - At our facilities, all incoming raw materials and components are thoroughly inspected to verify their compliance with specified quality standards. Our dedicated quality control team carefully checks the materials for any defects, damage or deviations from the supplied specifications . Only materials and components that meet our strict approval standards are accepted for production.

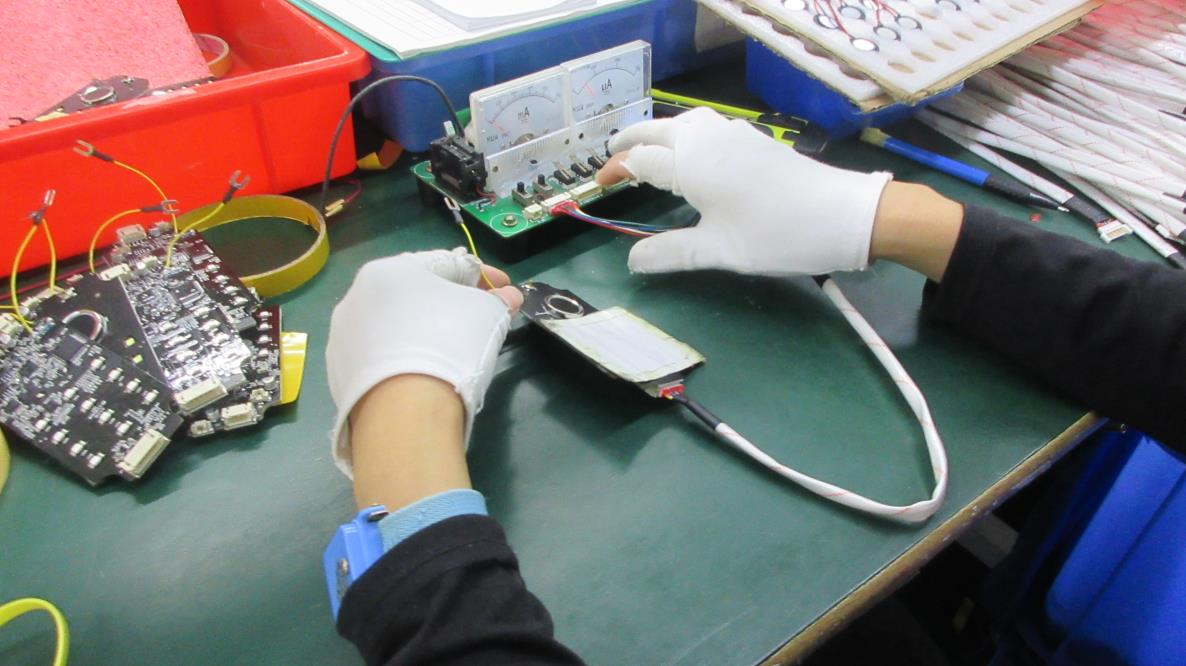

2. Process quality control: - During the manufacturing process, we conduct continuous quality checks to carefully monitor and verify each critical step. Our dedicated quality control staff conduct regular inspections to ensure that precise manufacturing procedures and specifications are strictly adhered to. Any deviations or non-conformities will be were promptly addressed and necessary corrective actions are being taken to address these issues.

3. Performance and functional testing: - Our lighting products undergo rigorous performance and functionality testing to ensure they exceed industry standards and meet customer expectations. Our quality control team conducts a range of tests, including durability, safety and electronic performance assessments, to Assessing product reliability Only products that successfully pass these tests are approved for further processing or shipment to ensure that the highest quality standards are maintained.

4. Final inspection and packing: - Each lighting product undergoes final inspection to ensure that it meets all quality requirements and is free of manufacturing defects. Our quality control team carefully verifies the appearance, functionality and performance of each product to ensure they meet the required standards. Approved Lighting products are then carefully packaged to ensure they are fully protected during transportation and storage, maintaining their quality until they reach the end user.

5. Random sampling and testing: - To maintain ongoing quality control, we conduct regular random sampling of finished lighting products. Randomly selected products are thoroughly tested to verify their quality, functionality and durability. This process allows us to identify any potential issues or trends, and take necessary corrective actions to prevent such problems from recurring and ensure that our lighting products always meet the highest quality and performance standards.

6. Continuous improvement: - At RHEIN LIGHT, we are committed to continuously improving our manufacturing processes and product quality. We continuously review and analyze customer feedback, conduct post-market surveillance, and conduct internal audits to identify areas for improvement. Insights gained from customer feedback and internal evaluations are used to update and refine our quality control procedures to ensure we continue to provide quality lighting products that meet and exceed industry standards and customer expectations.s.

At RHEIN LIGHT, our quality control processes ensure that our lighting products meet strict quality standards and are designed to achieve the highest level of customer satisfaction. We are committed to providing reliable, durable and safe lighting solutions that continually exceed our customers’ expectations .Commitment to excellence drives us to provide lighting products that not only meet industry standards but also exceed the expectations of our valued customers.